Medical Device Testing

Medical device industry quality practices remain dependent on operator-driven methods of inspection to identify flaws in braided or non-braided catheter-based products. Human hands or eyes continue to be relied upon to catch flaws in product that ultimately can become a medical device. SYNEO’s Accu-Test inspection options reduce the dependency on human factors while increasing the quality of the end product.

Accu-Test VIS

SYNEO’s custom Vision Inspection Systems are utilized in applications requiring detection or quality assessments of holes, marker bands, tip profiles and printed text or feature verification.

Accu-Test MIS

SYNEO’s custom Mechanical Inspection Systems are utilized in applications requiring detection or quality assessments of surface roughness, typically found in combination with micro-blasting or other surface roughening applications.

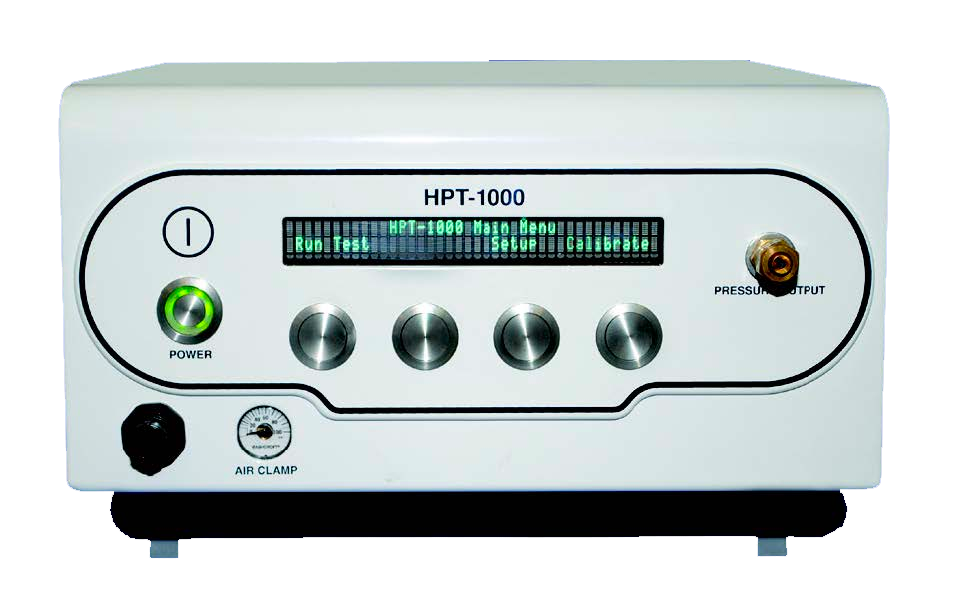

Accu-Test HVT

The Hydraulic Pressure Testers provide critical hydraulic test functions for balloon catheters and components, including tubing and balloons.

Pressure Leak Testing

GPL-501B: Gas Pressure Leak Tester

The Interface gas pressure leak tester, model GPL-501, is a tabletop machine used for nondestructive leak testing of catheter components using dry nitrogen gas.

GPL-5020: Gas Pressure Leak Tester

The Interface Gas Pressure Leak Tester, Model GPL-5020, is designed for rapid, non-destructive testing of catheters.

HPT-1000: Hydraulic Pressure Tester

The Hydraulic Pressure Testers provide critical hydraulic test functions for balloon catheters and components, including tubing and balloons.

PT-3070: Hydraulic Pressure Tester

The PT-3070 is ideally suited for testing small plastic pressure retaining components such as welded or bonded plastic components and tubing assemblies that are typically encountered in many disposable medical devices, i.e. balloon catheters.